The aseptic heat exchangers with filling machine are available in different types of configuration, depending on the characteristic of the product to be processed.

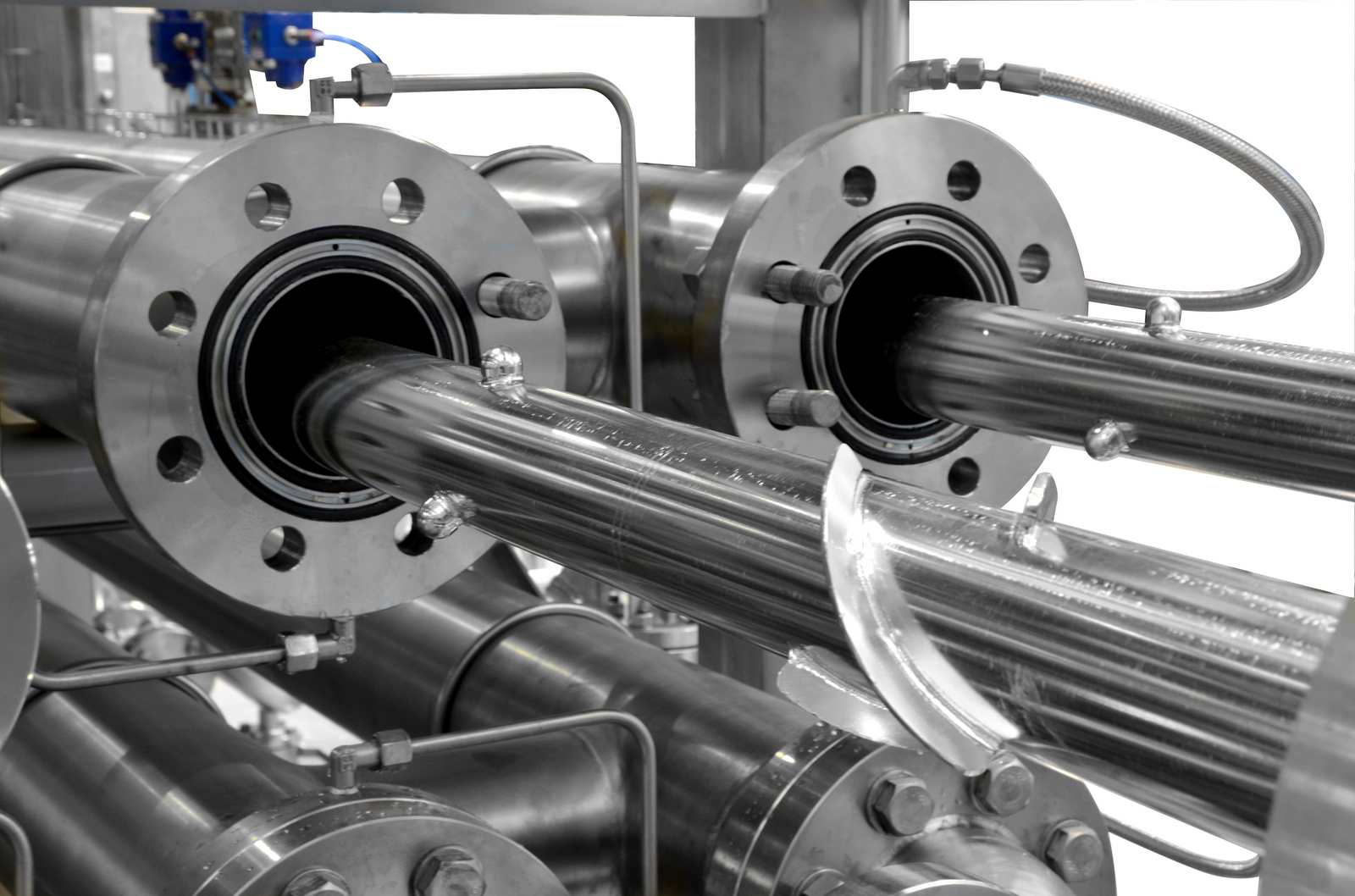

The Tube-in-Tube Sterilizer (LP) constitutes the core of fully integrated processing lines. The Tube-in-Tube Sterilizer Line (LP) is mainly composed of a Tube-in-Tube Heat Exchanger section, aholding section (sterilizing) and a cooling section that is connected to a filler machine.

Fast, reliable, cost-effective and efficient, Freefield technical staff constantly develops cutting-edge and customized solutions, in order to meet customers’ highest requirements.

Application

single strength / concentrated fruit and vegetable purees

Composition

Sterilizer with filling machine

Product data

| LOW PRESSURE HIGH ACID |

LOW PRESSURE LOW ACID |

|

|---|---|---|

| Viscosity | low | low |

| Type of Exchanger | tube-in-tube (4 tubes) | tube-in-tube (4 tubes) |

| Operating pressure | up to 30 bar (standard execution) | up to 30 bar (standard execution) |

| Flow rate | up to 10000 l/h | up to 10000 l/h |

| Product pH range | pH up to 4,5 | pH up to 7 |

| Product pump | low pressure pump | low pressure pump |

| Product holding time | 30 / 60 seconds with manual bypass configuration | 30 / 60 seconds with manual bypass configuration |

| Sterilization temperature | up to 115° C | up to 135° C |

| Final product cooling temperature (minimum) | +30° C (Aseptic filling) and +5° C (Non-Aseptic filling) | +30° C (Aseptic filling) and +5° C (Non-Aseptic filling) |

| Product receiving | vertical tank (optional deaeration system) or horizontal tank | vertical tank (optional deaeration system) or horizontal tank |